RB55 breaks new ground at Turney’s

Turney’s Limited are an arable and contracting business farming 1100 hectares of combinable crops – winter wheat, oilseed rape, winter beans, spring oats plus wild bird seed to various Countryside Stewardship and SFI features.

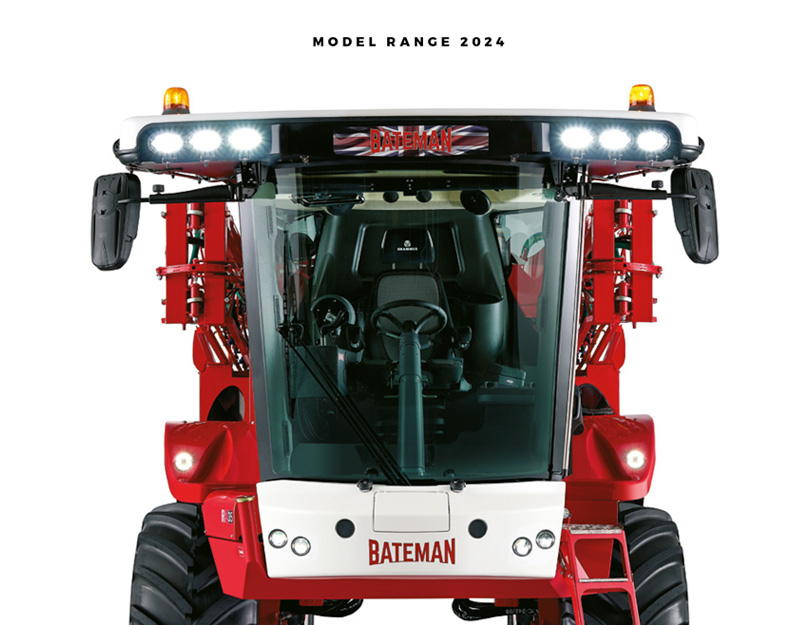

Turney’s run a Bateman RB55 with 5,600 litres and a 36-metre boom. The machine is also fitted with Pinpoint III PWM, BBL, E-Drive and Tankmatic filling.

Before taking delivery of the RB55 in 2023, the business ran an RB35 with 4,000 litres and a 30-metre boom. Because of the land parcel size, the decision was made to move to a larger sprayer, which led Turney’s into new territory. The RB35 had run on 710 tyres, would these still be the best choice of tyre for the RB55? Another consideration was whether the RB55 could run on just one set of wheels instead of two as had been normal practice on the 35. Giles Benson is Farm Manager at Turney’s…

“The farm here at Northampton is reasonably well drained. However, the block of land we’ve got over at Buckingham running up to Silverstone Race Circuit is quite hilly, quite heavy and isn’t well drained. We get a lot of wet spots and wet areas over there.

“Because we used to run the old 710’s at about 16 PSI, moving to a larger sprayer got us thinking about tyres. We wondered if there was a tyre which would cope with the additional tank capacity, but would run at lower pressures. If we could get away with one set of wheels, moving to 36 meters would result in fewer wheeling’s across the field. Also, one tyre would save the bother of changing to narrows right at the end of the season.”

During initial discussions with Bateman Technical Sales Manager Carl Goff various tyre options were evaluated. However, a particular tyre developed by Michelin had potential. Giles takes up the story… “We liked the sound of a 620 tyre that Michelin had developed. We had a long-standing contact at Michelin, we got in touch with him and he put us in touch with a colleague. We received a detailed analysis which showed that the 620 tyre had a larger footprint, even though it wasn’t as wide as the 710. The carrying capacity of this tyre was a lot greater than the 710, which meant we could run at lower pressure.

“Safety on the road was a key consideration. Because we are 18 miles between the two holdings, we didn’t want to be limited by road speed whether transiting on full or part loads. Michelin assured us that the 620 tyre would handle our road speeds, which was confirmed by an operator I know who had these tyres on his new sprayer.

“Following further conversations with Bateman we thought we should go for the 620 tyres. Bateman have a good working partnership with Michelin, between them there’s a lot of knowledge. We arrived at our decision fairly easily, we hoped it was the right one, but were happy with the new direction we had chosen.” So, has the decision paid off? Laurence Sykes is lead sprayer operator at Turney’s…

“I would say that we’ve travelled better on the surface of the soil than we did on the 710’s, especially in wetter conditions. During last autumn, it was wet when we were drilling and when we put the pre-ems on. We had the tyres set at 14 PSI at the front and 16 PSI at the back, it’s quite a squabby pattern, but you could hardly see where we’d been, in a sprayer which has another ton and a half capacity.

“Where it has cut in due to the tyre being thinner, but a longer footprint, when you cross it with another machine, you haven’t got that trench to dig through. It’s actually a shorter space for the tyre to travel across, so it’s even smoother.

“Our wheel spacings now match across the fleet, so there’s less tram line damage. We don’t physically drill a tram line anymore; we drill the whole field with no tram lines and then I put the tram lines in with the RTK on the sprayer.”

How have the 620’s performed when switching from field speeds to road speeds? Laurence again…

“Transferring from field to road is easy. There’s no complications and it travels very quickly on the road, the tyres don’t wallow, when you’re going around the roundabouts it feels very stable, which, with the flex in the tyre, you’d think would be more unstable.

“I would say that it has improved efficiency and because when you’re moving around on the road, it’s dead time and we’re travelling at higher speeds. With 5,600 litres on board, setting the pressures at 16 back 14 front you can still travel at 50kph fully laden.”

Without dwelling on the awful conditions faced by most farmers and contractors during last winter and this spring, how does the team feel the tyres have performed?

Giles… “It certainly had a good trial this winter and spring, should we say, in some of the conditions it’s been working in. The previous RB35 would probably have gone through, but would have made more of a mess.”

Laurence… “I have been pretty amazed, you think, ‘Oh, I’m digging in here’, and it will just plough on through with the horsepower that the sprayer produces and the grip of the tyres. The E-drive, causes the wheel motors to act independently, it will keep going in very tough

conditions.”

Tyres aside, how does Laurence find operating the larger RB55?

“We’ve literally just done all of our wild bird seed plots where I’m folded out to 12 meters, I don’t think I’ve ever gone through it as quickly as I did with the RB55. I’d say in the field you don’t notice the size at all or on the road. The only time you notice the size is when you reverse it into a shed, however, it comes with reversing cameras as standard, which helps.

“I really like the Bateman boom levelling, it makes a real difference to spraying on days which are challenging. The pulse width modulation is excellent, we’re much more accurate. The Tankmatic auto shut off fill has improved my efficiency for cleaning boxes and chemical cans away. Also, just keeping my induction hopper nice and clean and prepping cans as well.

“It’s a nice environment to work in, the seat is very comfortable, visibility is good from the cab, I can quite happily sit in there for 12, 14, 16 hours a day. Everything that came as standard has been a big bonus, such as the storage cabinets on the side and the LED light package. I must also mention the auto greaser, that’s been a real time saver for us, which is a huge benefit.”

Giles, summing up added…

“Conditions over the last few months have been a real test and I’m very pleased with how the sprayer has handled them. We’ve not regretted our decision regarding tyres. On the occasions that I’ve been spraying in the 55, I would echo Laurence’s comments, particularly on the boom levelling, which is absolutely brilliant, the pulse width modulation is very impressive too.

“During a recent meeting it was pointed out that since moving from 30 to 36 metres and a larger capacity tank, we are actually 33% more efficient. I think this speaks for itself.”

(Left to Right) Giles Benson, Farm Manager and Laurence Sykes, Lead Sprayer Operator.

Would you like to book a demo? Contact us today and arrange for the Bateman Demonstration Team to visit your farm.