Pinpoint III Envelop Pulse Width Modulation: Your questions answered.

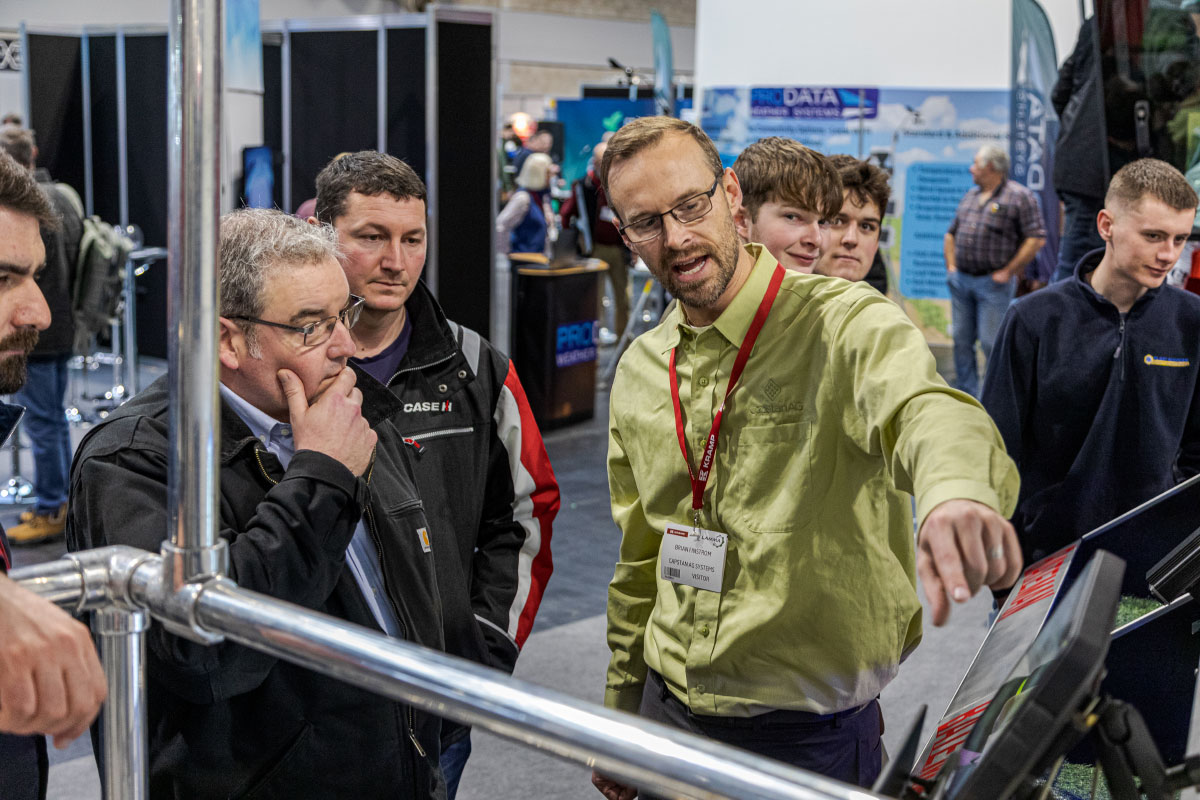

Capstan AG is our Pulse Width Modulation (PWM) partner. Brian Finstrom from Capstan recently joined us on our stand at LAMMA 2023 to demonstrate the benefits of Pinpoint III PWM. For those unable to attend LAMMA we’ve asked Brian a few questions on your behalf…

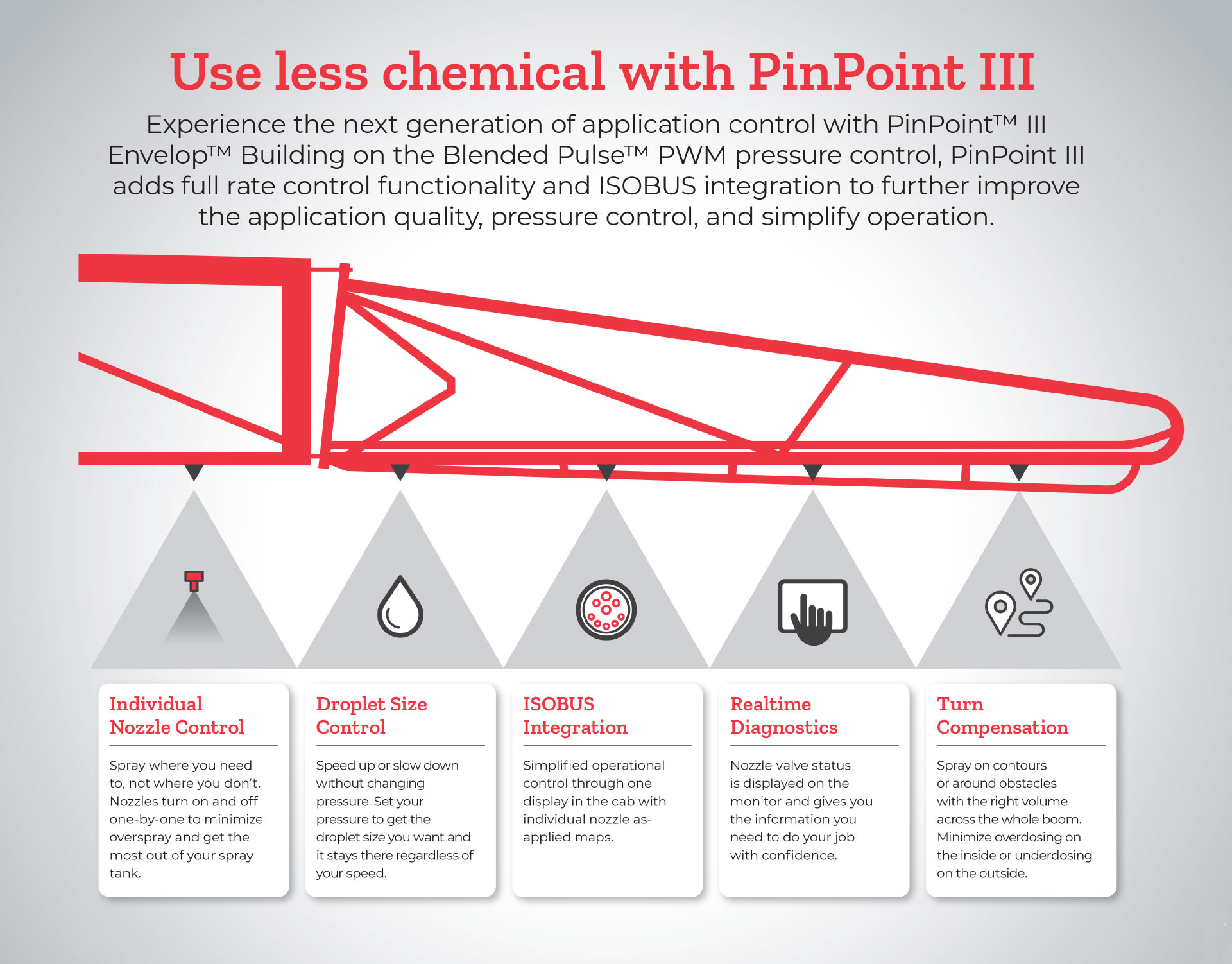

What is PinPoint III Envelop when compared to PinPoint II?

PinPoint III has been in the works for a while as we were wanting to make not just an ISOBUS version of PinPoint II, but to take advantage of the option to fully take over the flow control of the liquid system. Our goals for the product were driven by the feedback we had received from users that had PinPoint or PinPoint II, which were developed before any other PWM nozzle control systems were available in the market.

We have had a faithful group of operators for many years that use their sprayers throughout the spray season that we can count on to give us their perspective on what works or not, PinPoint III is ultimately meant to address their needs and hopefully most of their wants.

What are the differences between PinPoint II and PinPoint III?

If you were to just look at the hardware, there is actually very little difference with the exception that there is not a separate display in the cab of the sprayer. PinPoint III uses an ISOBUS Virtual Terminal as the interface so the operator will interact through their in-cab field computer which for most Bateman machines is an Ag Leader or Topcon. The main ECU for PinPoint III is also new but outside of that, the boom parts are all pretty much the same. That also means that PinPoint II systems can be upgraded to PinPoint III in the future if desired.

Pictured: Brian FInstrom discusses the features of Pinpoint III on the Bateman Sprayers stand at LAMMA 2023.

The software for PinPoint III is where the real changes exist:

- PinPoint III is a full ISOBUS rate controller which means that the Capstan system is solely responsible for applying the desired rate. This is different from PinPoint II in that PinPoint II had to interact with another rate controller to do pressure and flow control. The benefit for PinPoint III is that there is no competing system trying to adjust anything while spraying. It allows for faster rate response and easier troubleshooting.

- PinPoint III is also an ISOBUS Task Control client for section control. That means that it tells the field computer (Ag Leader, Topcon, etc.) all of the boom information like how wide it is and how many sections it can control, and then the field computer is able to turn those sections on and off. This lets your field computer map individual nozzle sections for as-applied information rather than the normal 3m or 6m sections. This is different than PinPoint II, which worked off of a separate map and sometimes there might be a mismatch due to settings. With PinPoint III, that potential issue goes away as long as the boom location on the machine is set up correctly.

- Software updates, though hopefully not frequently needed, are also easier with PinPoint III as the updates can be loaded via a smartphone. No USB drives or computers will be required under most circumstances, which allows the faster deployment of new features when they become available. The smartphone app also allows for nozzle checks from behind the machine if catch tests or nozzle checks are desired.

How about the differences between PinPoint III and other systems on the market?

I would understandably be biased in comments about competitive systems available so my thoughts on those systems would be less helpful than to simply let people know that when they are working with a Capstan System, they are working with the people that brought PWM into the industry in the first place. Our team of engineers and field staff have heard just about every question that one can think of and walked fields with customers that have had problems to work through. We also manufacture and design our systems, both hardware, software, and components, in-house so we are able to find issues quickly and implement solutions faster than most larger companies.

Does that include your nozzle valves?

Yes, in fact, we have actually launched a new design that is aimed at improving the longevity and performance of our valves. We call them our Spitfire valves. We have been testing them extensively both in our laboratory and also with field units in a few countries around the world to make sure that our results are checked against real-world use. So far, we have been very pleased to see that the field performance agrees with our lab torture tests that the valves and plungers are lasting significantly longer than our baseline valves that we have been selling for many years.

Is PinPoint III easy to setup and use?

Bateman have hit the ground running with it. The fundamental similarities to PinPoint II, along with the simplified machine connectivity, make adjusting to PinPoint III easier. Operators with PinPoint II experience seem to take to using it quickly as well. If in doubt, we have several owners that I am sure would be happy to share their experience.

Would you like to book a demo? Contact us today and arrange for the Bateman Demonstration Team to visit your farm.