Crop sprayers for farmers and contractors

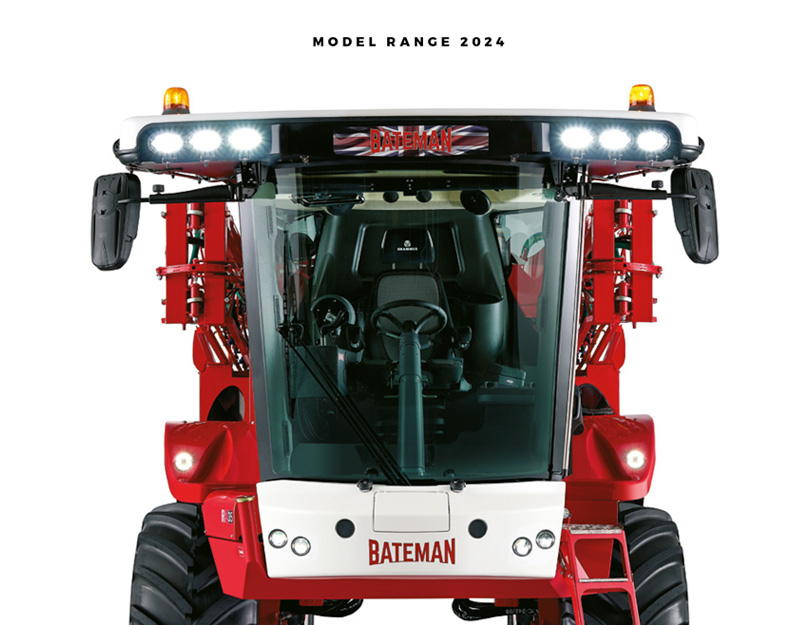

Quality design delivering outstanding productivity is the Bateman philosophy.

We know our crop sprayers inside out. Every last detail of a Bateman sprayer is designed and built by us to deliver outstanding performance in the most efficient way.

Three crop sprayers are currently available in the Bateman range – the RB26, RB35 and RB55.

Covering all spraying requirements, each model delivers class-leading longevity and efficiency in the field to ensure every second in the cab counts. And with a host of comfort-enhancing features that make operation easy, these are machines that you will be happy to work in when crop spraying over long hours.